Rapid prototyping is progressively becoming an admired and influential process of product development that enables companies to make inexpensive prototype models of their new product designs quickly enough, which they can use in the testing process for user feedback and reduced time-to-market.

Quick feedback and design iteration

The capacity to rapidly manufacture more than one prototype design enables developers to present working models very early during the initial designing stages. Getting early feedback on tangible products makes it much easier to identify and fix design mistakes when they are still easy to change. The quicker refinement method through user testing usually requires less rework than traditional prototyping methods. Companies can complete multiple iterations and optimize the design more quickly.

Reduced development costs

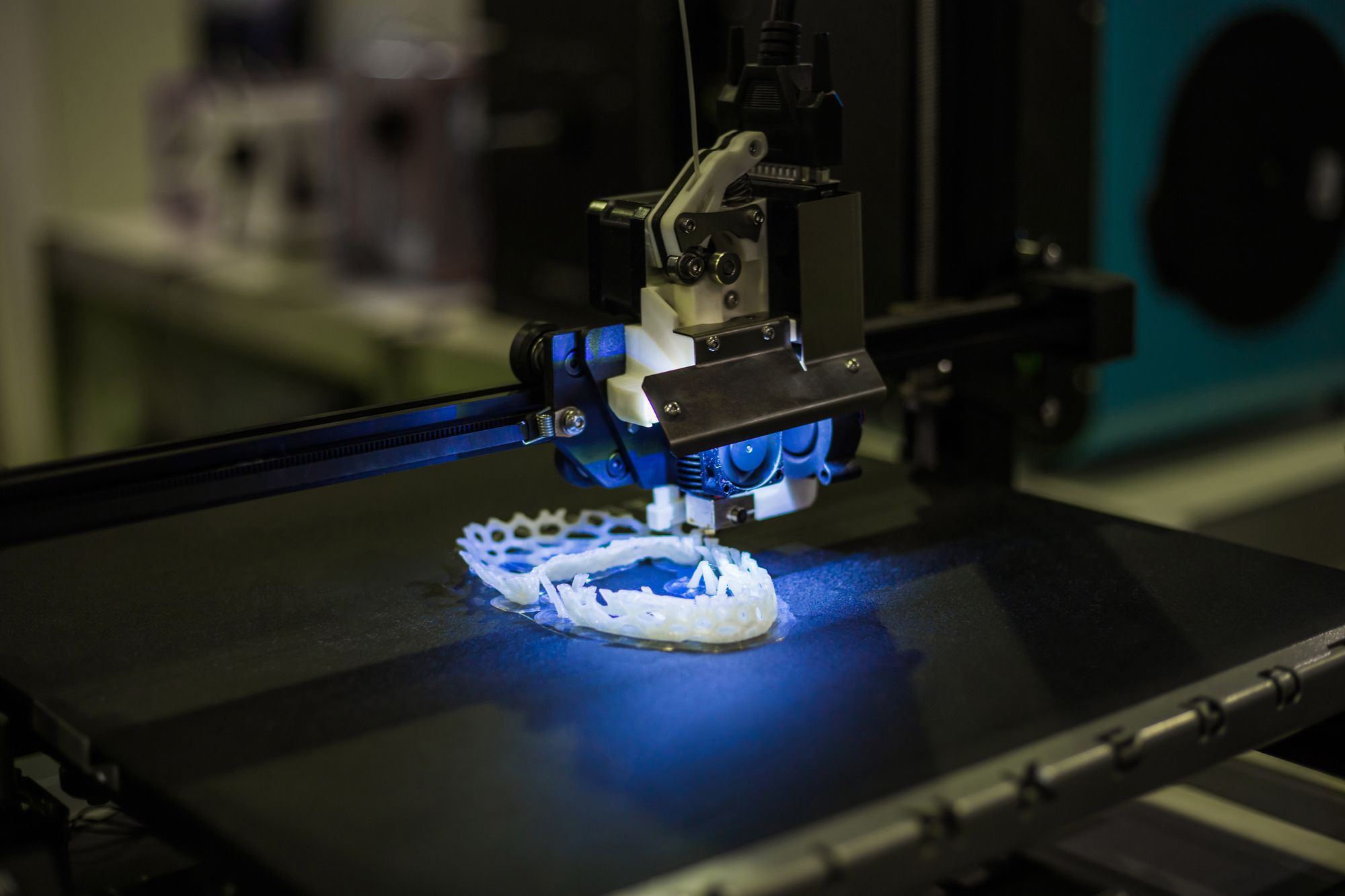

Construction of early prototypes using rapid prototyping technologies like 3D printing or CNC machining is considerably cheaper than traditional prototype tooling and manufacturing. Early issue spotting prevents having to redo production tooling and manufacturing setups later, resulting in huge time and cost savings. Rapid prototyping supports early, cheap failures, a critical feature of good design.

Enables concurrent engineering

Prototyping speed-up facilitates concurrent engineering as different teams work simultaneously on other aspects of product development. With the fast production of prototypes that can be shared among departments, collaboration like this becomes much easier across cross-functional teams. It will help teams promptly to identify the integration problems that may make them go into costly rework processes, thus reducing development time and ultimately delivering faster time-to-market.

Allows more innovative designs

There are fewer restrictions on the manufacturability side due to rapid prototyping techniques compared to traditional designs. Techs such as 3D printing mean that elaborate geometries or shapes that could not be fabricated at all or, at best, would have been very expensive can be manufactured easily. It is because companies have more room to play around with innovative and bold design ideas since complex form factors are no longer the reserve of big organizations.

Facilitates mass customization

The flexibility and responsiveness enabled by rapid prototyping systems also facilitate mass customization producing customized products and features tailored to individual users at mass-production prices. Rapidly turning digital designs into physical prototypes helps companies provide a high product variance to customers at a low cost. Customized production batches become more economical.

Summing up

Fast prototyping quicken development efficiencies, decreases costs, promotes collaboration, allows more design innovation and enables mass customization. Consequently, such a combination of faster iteration, higher innovation, lower risks, and greater stakeholder engagement leads to products that satisfy the needs and, hence, have a higher chance of success upon market release.