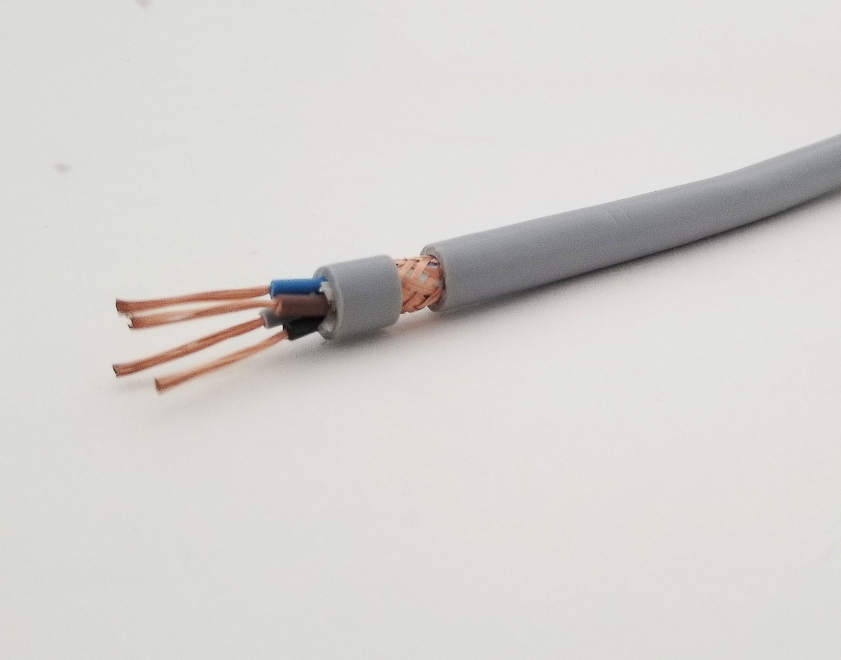

Silicone, TPE, or TPU cables are commonly utilized in medical device interconnectivity or accessories. PVC cable is another option, albeit it is typically used for disposal.TPU and TPE have emerged as the primary medical extruded or over-molding materials in certain nations where reusable medical equipment is required to reduce healthcare costs and environmental impact. So, how do you choose between ul tpu cable and TPE cables for your project? How do you distinguish between TPU and TPE? The key characteristics and distinctions between TPU and TPE can be used to begin distinguishing between the two types of cables:

The Distinctions Between TPU and TPE Cable

Physical and chemical characteristics can be used to distinguish TPE cable from TPU cable.

-

Hardness

TPU generally feels rougher and tougher with significant friction, whereas TPE seems softer. This difference in hardness can be crucial in your project. For instance, TPE cable typically ranges from 60A to 85A in the cable extrusion field, with a hardness range of 0~100 A Shore. Too much elasticity is unsuitable for the extrusion of cables, which could affect the durability and performance of your project.

The most frequent TPU cable hardness range is 75A-85A; less than 75A is rarely utilized in practice. TPU hardness ranges from 35~90A Shore (50~80D). 35–75A hardness TPU is not suited for cable extrusion; the final average cost of soft TPU cable will be more because the softer TPU’s sides are more expensive. The cable’s look is rugged to regulate during the process. For sex dolls or sex toys, too-soft plastic material—whether it be TPE, TPU, PVC, or silicone—is typically utilized.

-

Density/Specific Gravity

Selecting the appropriate density of TPE materials is crucial in applications where the cable must dive or float on water, such as floating cables.TPE has a consistent specific gravity of 0.5 to 2.0 g/cm^. Foamed TPE-specific gravity is shallow and ideal for making floating cables. The density range of low-capacitance cables (TPU ) is smaller than that of TPE. It usually ranges from 1.06 g/cm³-1.25 g/cm³; foamed TPU is not used as regularly as foamed TPE. So, TPU cable applications are not as comprehensive as TPE cables.

-

Mechanical Potency

Comparing TPU and TPE cables, ul tpu cable cable is stronger mechanically in terms of resilience, abrasion resistance, and wear resistance

-

Oil Resistance

In several areas, including oil and grease resistance, TPU outperforms TPE. TPU’s superior oil resistance can provide security in your selection, as you know that your cables are well-equipped to withstand challenging industrial environments.

-

Chemical resistance.

The burning Odor of TPU smells strong while burning.TPE has a lovely scent.

Advice For Selecting Between TPU And TPE Cable

Generally speaking, the application should be considered before deciding whether to use TPE or TPU cable for your project. This is especially true for industrial applications, where aspects like processing, costs, and physical, chemical, and even biological qualities must be taken into consideration. When you want to use this cable for daily or commercial use, TPU cable feels better overall than TPE cable (assuming the same level of hardness). Businesses may benefit from increased user attraction and positive economic effects.